Simulation-Based Product Innovation: Endless Possibilities

Simply put, the seemingly impossible is possible with simulation. We can change the world through the power of simulation, and in many areas and ways, we already have. Simulation is transforming product innovation across nearly every sector.

From the earliest stages of design and analysis, throughout the product lifestyle, we see simulation improve workflows and increase quality and accuracy, while reducing risks and costs. That’s a win win.

The Future of Simulation-Based Product Innovation

But today, more than ever, we see endless possibilities with simulation because of advances like artificial intelligence (AI) and machine learning (ML). I had the opportunity to speak about this at Seagate Technology’s annual Tech Review earlier this month.

Seagate, a global leader in mass data storage solutions, implements Ansys’ best-in-class Multiphysics simulation software during product innovation spanning everything from component development to the full assembly of hard drives. But how much further can we go with simulation? What else can we do?

To explore these questions, Seagate invited me to join their internal conference and deliver the keynote presentation of its opening session.

I was delighted to speak to the Seagate engineers about the power of simulation-based product innovation and our Ansys long-term strategy, leveraging things like AI/ML, high-performance computing (HPC), and digital twins.

To demonstrate some of these advantages, I shared a presentation: “Future Directions of Simulation-Based Product Innovation,” which covered the impact of simulation throughout the product lifecycle across industries and the boundless possibilities we are advancing toward.

How Artificial Intelligence Enhances Simulation

As AI/ML continues to impact every industry around the world, I highlighted this area by sharing use cases of AI/ML’s influence on simulation.

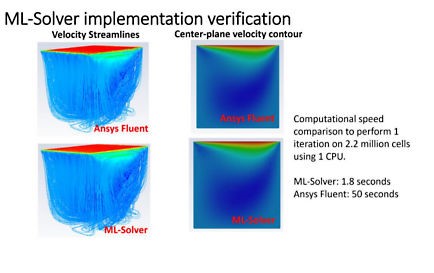

From employing ML to automatically set parameters in Ansys Discovery and increase productivity to leveraging ML-based flow solvers to enable augmented simulation, AI/ML not only impacts simulation, but accelerates and enhances it. Further, engineers in the audience learned how AI/ML affects engineering design through topology optimization, while company executives gained insight into how AI/ML improves business operations by, ultimately, reducing costs.

To dive deeper into AI/ML-powered process integration and design optimization, I discussed how AI/ML can be applied to Ansys optiSLang to advance inductor building blocks. With AI/ML-powered simulation, engineers can produce synthetic building block models with the highest possible accuracy, sparing exertion and time.

Seagate Technology Applies Simulation-Based Solutions

Seagate is committed to incorporating simulation into its technology and business strategies. I shared a panel at Simulation World 2020 with Seagate’s CTO John Morris, and we meet regularly to discuss simulation prospects.

Most recently, Seagate embraced Ansys’ tools in the development of its latest recording technology, Heat-Assisted Magnetic Recording (HAMR), which enables higher-capacity hard drives by increasing the data bit density of each disk.

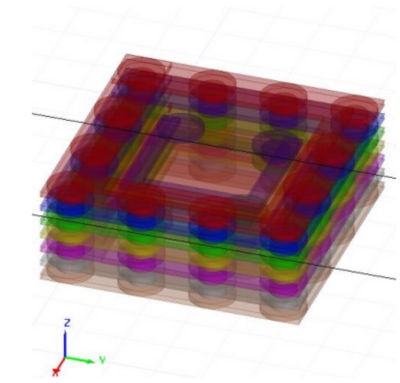

Throughout HAMR’s development, Seagate integrated Ansys Mechanical to assess thermal effects in thermo-mechanical design. Seagate has begun to use optiSlang to accelerate HAMR system optimization. And with Ansys’ universal platform of products, Seagate engineers can easily shift to other critical areas such as laser light path modelling with Ansys Lumerical.

Building on our longstanding relationship, Ansys and Seagate recently entered into a multiyear agreement to expand Seagate’s use of Ansys’ simulation solutions worldwide.

I look forward to seeing what Seagate and simulation continue to make possible.

To learn more about Seagate’s products, solutions, and innovation head to The Leader in Mass Data Storage Solutions | Seagate US.

Author

Prith Banerjee

Chief Technology Officer, Ansys

Related Posts